Bioquell Qube

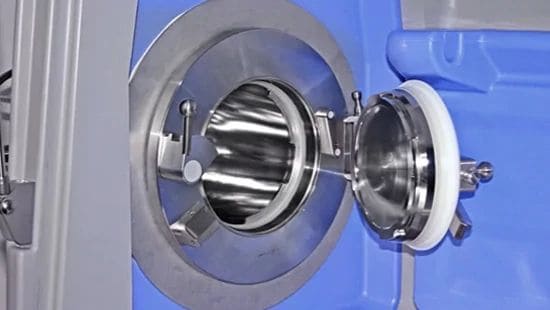

Aseptic Isolator

Create an aseptic workspace with Ecolab’s Bioquell Qube, a configurable isolator integrated with Bioquell hydrogen peroxide vapor technology. From its unique design to rapid cycle times, the Bioquell Qube provides the aseptic area you need to keep your research or production on track.

Benefits of Bioquell Qube

Improve workflow and productivity with the Bioquell Qube, and create a Grade A/ISO 5 environment inside the isolator.

Benefits of the Bioquell Qube include:

- Built-in Bioquell 35% hydrogen peroxide vapor technology

- Hydrogen peroxide cycles complete in as little as 20 minutes

- 2, 4, or 6 glove options with up to 2 material pass-throughs or RTPs

- Constructed of durable polypropylene and 316 stainless steel

- Air inlet cooling for heat-sensitive materials

- 4 levels of environmental monitoring

- Data logging with 21-CFR Part 11-compliant software

- Built-in screen with camera to record and display worksheets

- Switch between positive and negative pressure using the touchscreen; no need to change filters or take additional actions

- After the order date, can often be installed and validated in just 12 weeks

The Bioquell Qube is ideal for:

- Sterility testing

- Gene and cell therapy

- Small batch production

- Drug compounding

- Cytotoxic and hazardous drug preparation

Why Choose The Bioquell Qube?

Productive

Process materials in the main chamber while you work in another. Typical aseptic-hold retention is 7 days — customize this timing to your protocols.

Efficient

A cycle can be complete in as little as 20 minutes, depending on load specifications. After you order the Bioquell Qube, installation and validation is complete in as few as 12 weeks.

Adaptable

Up to 3 chambers (2 gloves per chamber) and 2 material transfer areas to meet your workflow needs. Positive and negative pressure capabilities.

Assured

Customized validated cycles support ISO 5/EU Grade A environment; GMP compliance; unidirectional airflow in accordance with GMP Annex 1; 21-CFR Part 11-compliant data-logging software available.

Efficient

Four levels of environmental monitoring for your viable and nonviable particle needs. Ability to incorporate the Merck Millipore Sigma Symbio Flex Sterility Pump.

Integrated

Built-in Bioquell hydrogen peroxide vapor technology for repeatable results. Easy-to-use touch-screen. No HVAC connection required.

Watch the Bioquell Qube in Action

See Modular Configurations

The Bioquell Qube has several configuration options.

Use one to three chambers, with up to two optional exterior/material transfers.

Examples of Bioquell Qube Applications

Bioquell Qube for Cell and Gene Therapy

Sterility Testing with Bioquell Qube

Related Products and Accessories

Environmental Monitoring

Monitor aseptic environmental conditions with four modes, ranging from manual to fully integrated particle monitoring with both viable and nonviable particle-counting options.

Sterility Test Pump

If you choose the largest Qube option with three chambers, you can add up to two integrated Merck Millipore Steritest Symbio Flex sterility test pumps. This helps to simplify operations and free up workspace.

Glove Sleeve System

Our patented glove sleeve system removes creases in both the sleeve and the glove. Includes smaller and lighter Safe Change Cuff Rings. Design helps ensure that all areas of the Bioquell Qube are contacted by hydrogen peroxide vapor.

Rapid Transfer Port

Aseptic transfer of materials in and out of isolators with no break of containment or effect on ambient characteristics. Available in both 190mm and 270mm.

About Hydrogen Peroxide Vapor

During a bio-decontamination cycle, Bioquell technology fills an enclosed area with 35% hydrogen peroxide vapor. In just one cycle, this vapor provides a 6-log sporicidal kill on exposed surfaces. Unlike chemical sterilants that can leave toxic residues behind, hydrogen peroxide vapor breaks down into water and oxygen once the bio-decontamination cycle and aeration is complete.

Validation

To meet regulatory requirements, you may need to deliver proof that your bio-decontamination solution performs as it should. Ecolab provides trained engineers and the validation documentation you need to comply with regulations.

FAQs About the Bioquell Qube

Do you offer 21-CFR Part 11 compliance?

Yes, we offer an optional data logger for this purpose.

Can I bring tubing or cables into the Bioquell Qube?

We have an option for fitting a floor-mounted one-inch triclover port in each chamber. This allows you to bring in liquid lines or cables securely into the body of the Bioquell Qube.

Can you set alarms for the temperature inside the Bioquell Qube?

Yes.

Are there different leak tests programmed for the Bioquell Qube?

Yes, there are leak tests programmed for both positive and negative pressure.