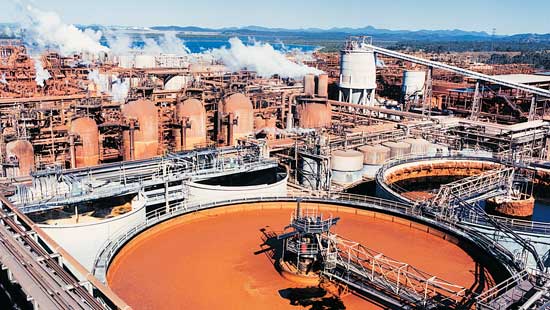

Alumina and Bauxite

Tailored Solutions for the Bayer Process and Alumina Refining

Water – A Critical Resource for the Bayer Process and Alumina Refining

Today’s alumina and bauxite producer is constantly challenged to improve safety, profitability, efficiency, and product quality while helping to sustain the surrounding environmental resources. Water plays a critical role in virtually all mining and mineral processing activities. It is a strategic resource with decreased availability and growing demand. Most of the water in the Bayer process must be evaporated, which ultimately increases energy consumption.

Nalco Water addresses this challenge head-on, with alumina processing aids that maximize productivity while minimizing water and energy consumption. With global success across a variety of alumina refining operations, Nalco Water tailors solutions that meet the unique needs of water-constrained environments.

Performance Through Solutions

Nalco Water is a partner that delivers economic and environmental value. By focusing on the entire alumina refining process, we help increase recovery and productivity while conserving energy, water, and raw materials. Using our alumina processing aids, our approach results in optimized productivity and throughput, which can positively impact our customers' bottom line. We use decades of industry experience, innovative technologies, local on-site expertise, and a global network of research labs and personnel to deliver the alumina processing results you need.

Success Stories

Improving Profitability while Saving Water and Energy — Nalco Water Drives Results with RRA™ Flocculant

At an Indian alumina processing plant, Nalco Water was commissioned to help reduce the amount of chemistry used while maintaining production and efficient handling of waste, specifically red mud tailings. Nalco Water’s RRA™ flocculant replaced a conventional synthetic flocculant with 32% lower consumption, leading to significant cost, water, and energy savings. Download the case study below to learn how Nalco Water partnered with the plant to help them become the lowest cost alumina producer in the world.

Extending the Life of Mud Washer Leads to Significant Productivity Improvements and Cost Savings

An alumina refinery needed to extend the life of one of its critical red mud washers. The washer, used to recover high-cost caustic soda, required a solution that reduced the formation and growth rate of scale. By introducing SCALE-GUARD™, Nalco Water was able to help extend the life of the washer from 180 to 200 days and reduce the thickness of the scale by 50%, making it easier to clean. Download the case study below to learn how Nalco Water helped the refinery ultimately save over $110,000 in costs by improving washer productivity.

Authored Articles

Scale Formation Control on Lead Washers

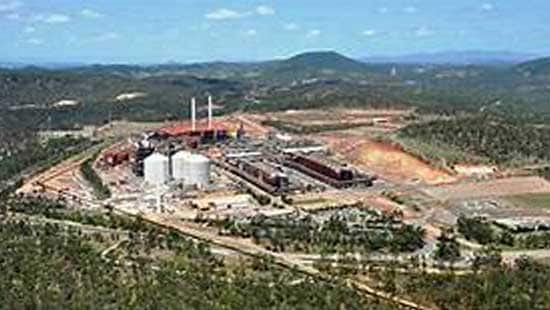

Scale Formation is one of the most critical challenges to control the mud settling performance in a lead washer and to extend the vessel life. ScaleGuard™ was trialed at Rio Tinto Yarwun alumina refinery with promising results.

Scale Inhibition in Washers

At Hindalco’s Muri alumina refinery in India, ScaleGuard™ was applied to the first washer to extend the washer life and improve overall efficiency of caustic recovery.

Management and Control of Sodium Oxalate Precipitation in the Bayer Process

Alumina Processing Solutions

Learn how our solutions for alumina refining can help you maximize productivity, optimize costs, and minimize water consumption.